EED - Single deduster

EED - Single deduster

Anywhere where there is only a limited number of dust sources to be cleaned..

It is low-maintenance, versatile and energy-saving - we developed our EE-D single deduster for the cleaning of production works with a limited number of dust sources used anywhere where there is only

a limited number of dust sources to be cleaned.

Application area

Dedusting of production facilities/machines with limited number of dust sources.

The functional principle

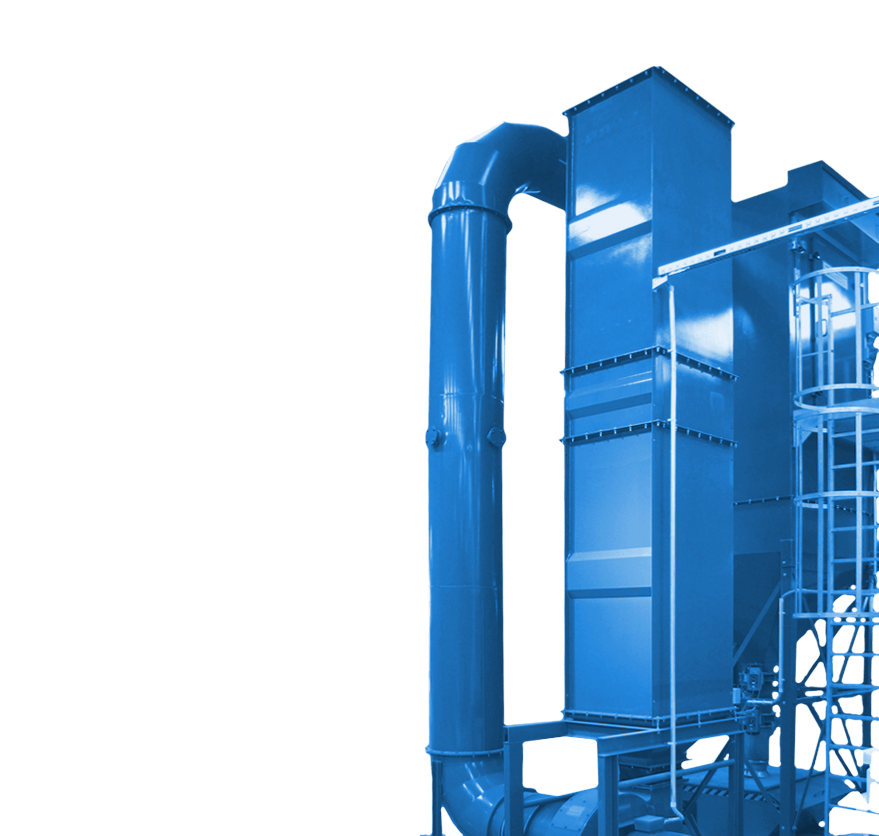

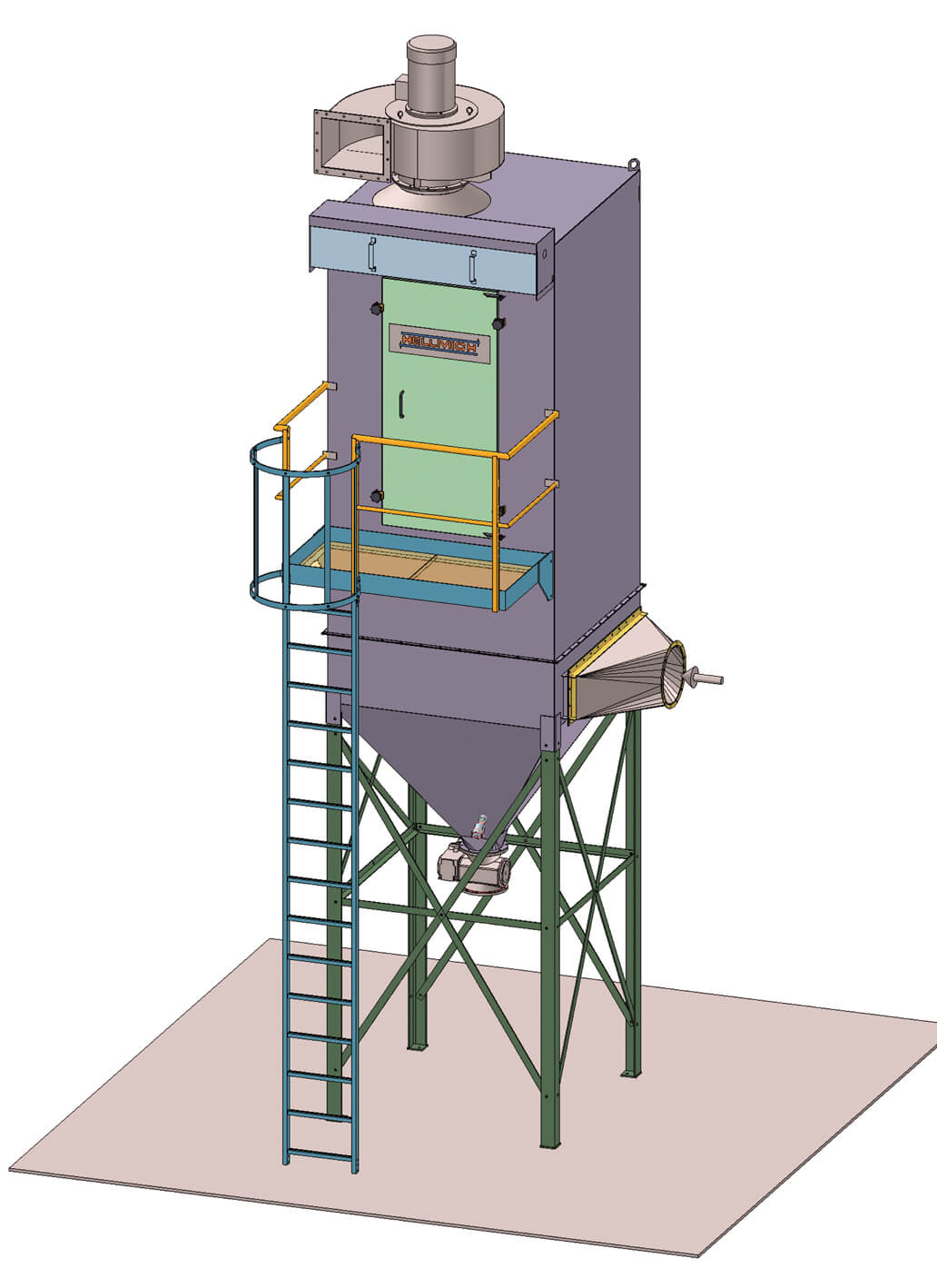

Our EE-D single deduster can be used anywhere where there is only a limited number of dust sources to be cleaned. It has been designed for airflow quantities of between 4,000 and 13,000 Bm³/h. The basic component in the EE-D is a filter housing with a dust collection hopper, both of which are made from stable sheet steel. The necessary fan is mounted on top of the filter housing. The dedusting facility contains several filter hoses which are compiled to form groups. The groups are successively cleaned using a compressed air wave passed through a solenoid valve. The compressed air wave causes a rapid pressure increase in the filter hoses, which then results in a brief reversal of airflow through the filter hoses. The dust cakes are loosened and fall down. Cleaning off is triggered by an adjustable differential pressure switch as soon as the dust-laden filter hoses have reached the preselected resistance. The cleaning process is inexpensive because it only takes place when required. The compressed air quantity necessary is dependent on the type and quantity of dust.

The duration of the cleaning impulses can be set between 0.1 and 1 seconds. The filter hoses are fixed using a snap steel band and double bulge tape. Assembly and dismantling can be carried out without tools. The single deduster can be operated extremely economically and with low energy consumption at an application range of between 4,000 and 13,000 Bm³/h.

The suctioned-off material can be discharged or transported away as follows:

- Double flap valve or rotary gate valve/screw conveyor, conveyor belt etc

- Pneumatic transport

- Self-tipping transport bucket for forklift operation

Advantages

- Low space requirements

- Low energy consumption

- Stable construction

- Wide range of applications

The technology

The fully welded steel plate base frame of the stable steel plate construction consists of a filter housing with a dust collection hopper. An add-on fan is fitted on top of the filter housing to save space. Several filter hoses are compiled to form a group, and these are successively cleaned off using a compressed air wave via a solenoid valve.