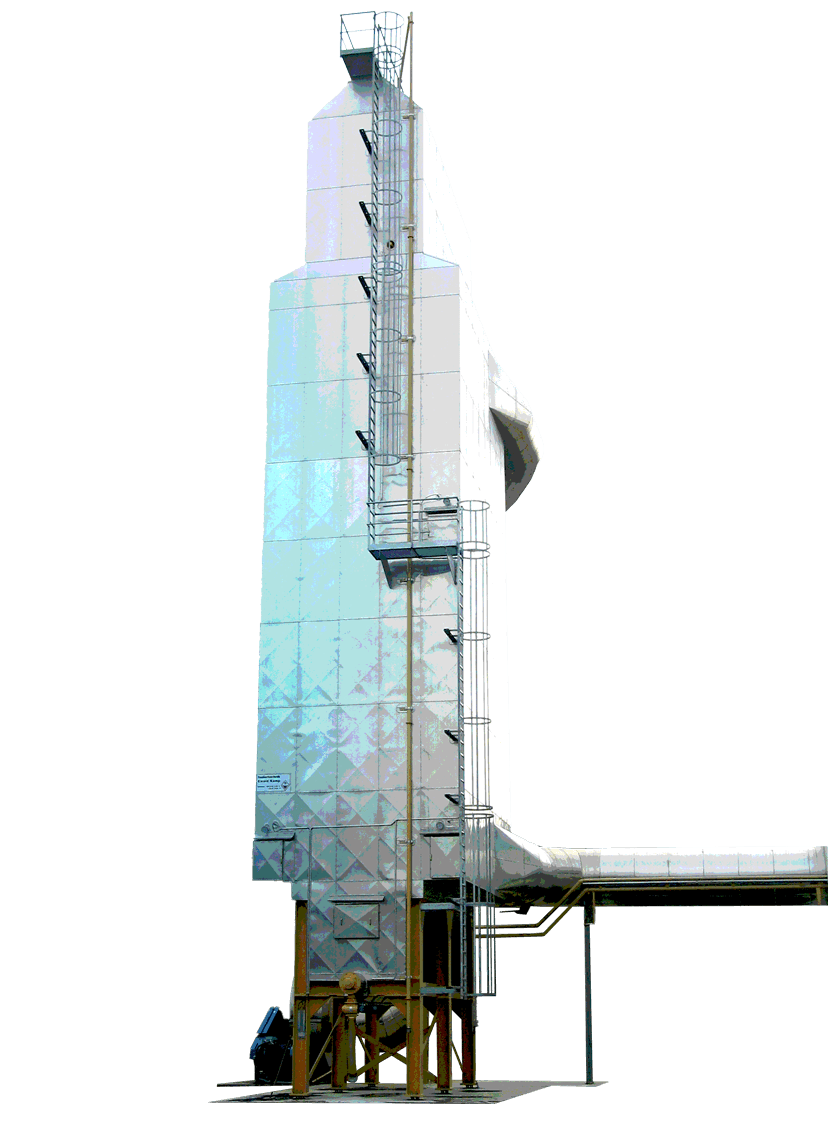

SGA packed bed counterflow absorber

SGA packed bed counterflow absorber

The Hellmich aggregate bed counterflow absorber (SGA) is similar to the fluorine cascade absorber in its method of operation.

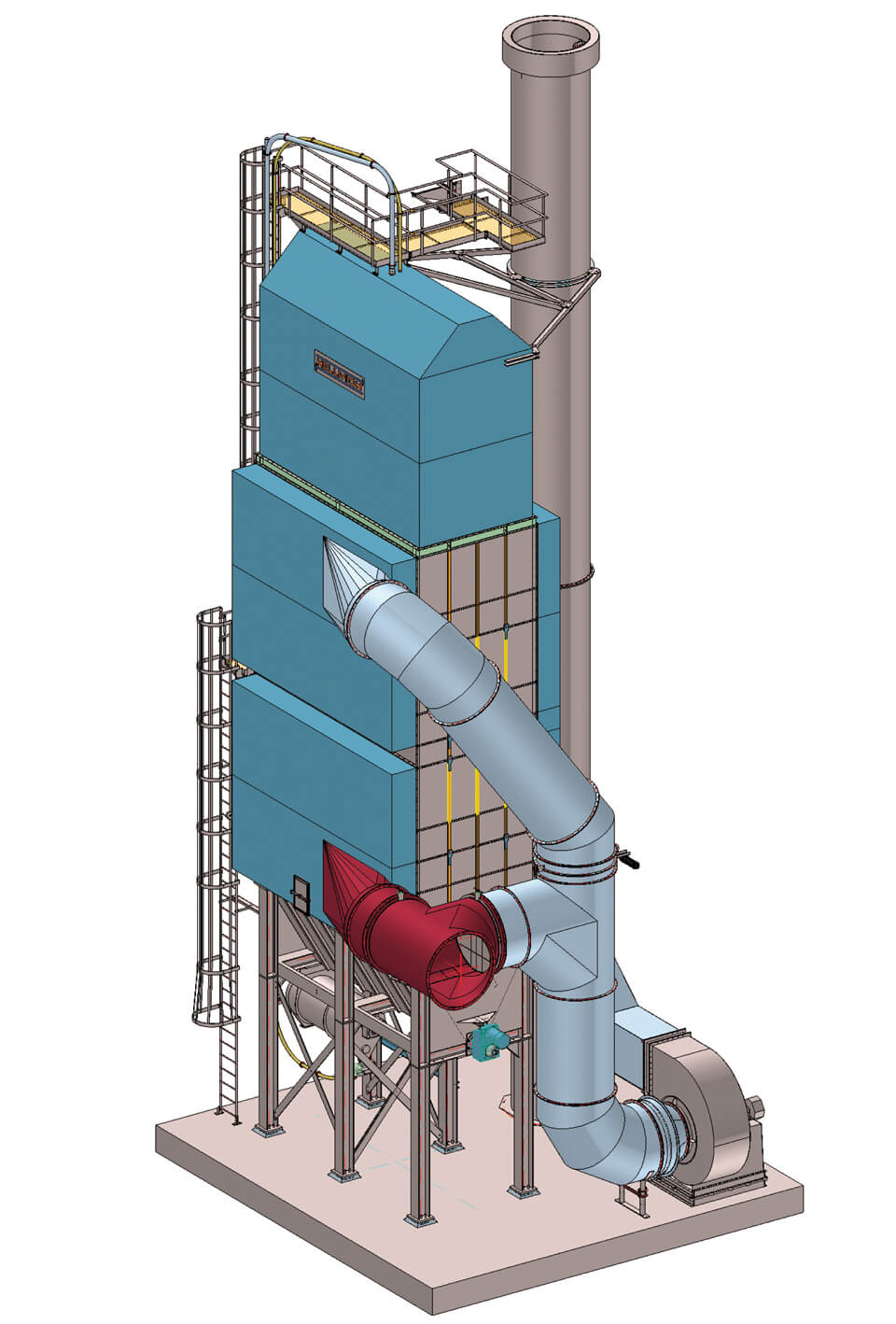

The SGA reduces high SOx concentrations down to below 300 mg/Nm³. The counterflow absorber uses reaction chambers connected in series (cascade blocks) in contrast to the flooring cascade absorber. Since the absorbent areas are connected in series, the flue gases are fed through the absorbent material several times, which results in high absorbent process efficiency and a simultaneous reduction in contaminants.

Application area

High fluorine and SOx concentrations.

The functional principle

The packed bed counterflow absorber (SGA) is similar in function to the fluorine cascade absorber. However the SGA is different because the reaction chambers (cascade blocks) are arranged in series, and this allows it to reduce SOx concentrations from around 2,500 mg/Nm³ to below 300 mg/Nm³.

This type of equipment is especially advantageous because there are no moving parts which contact the flue gas flow. Since the absorption areas are connected in series, the flue gases are fed through the absorption material several times, which results in high absorption process efficiency and a simultaneous reduction in contaminants.

The SGA is specially designed for operation at higher temperatures. A man-made calcium carbonate granulate is used as a absorption material.

If sulphur dioxide levels are low, it is also possible to use conventional limestone chippings.

Just like all flue gas cleaning equipment produced by Hellmich, the packed bed counterflow absorber stands out through its extremely low operating costs.

Advantages

- Low operating costs

- High absorbent usage

- Low-maintenance due to lack of moving parts in flue gas flow

The technology

Since the reaction chambers (cascade blocks) are connected in series the flue gases are fed through the absorption material several times, which results in high absorption process efficiency and a simultaneous reduction in contaminants. The SGA stands out through its ability to operate at higher temperatures.