HKD III - Dedusting facility

HKD III - Dedusting facility

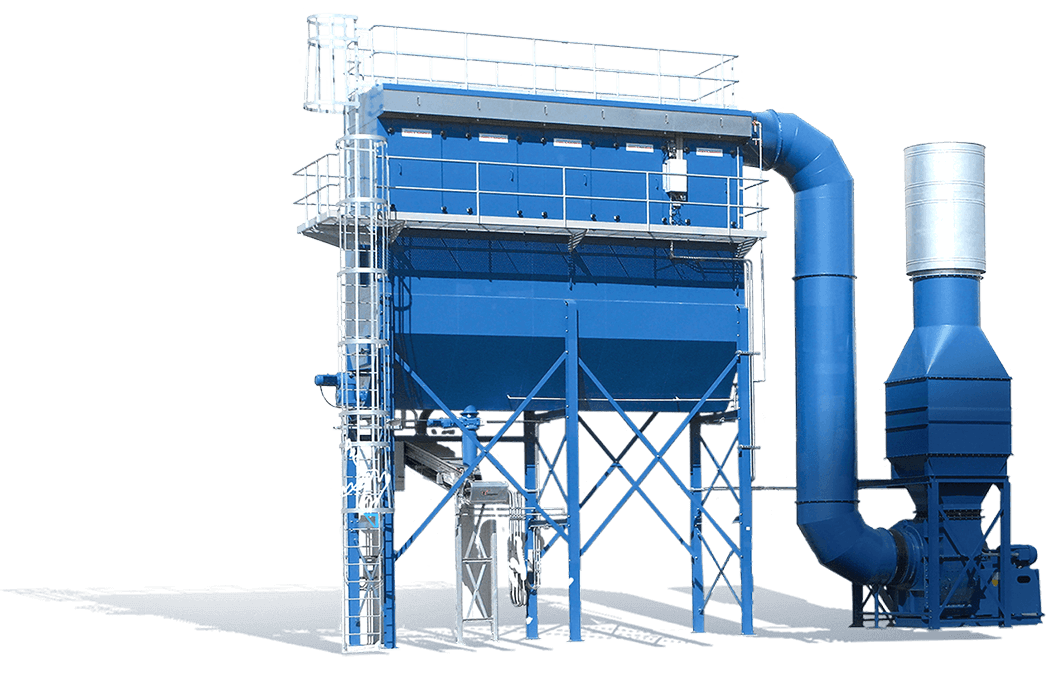

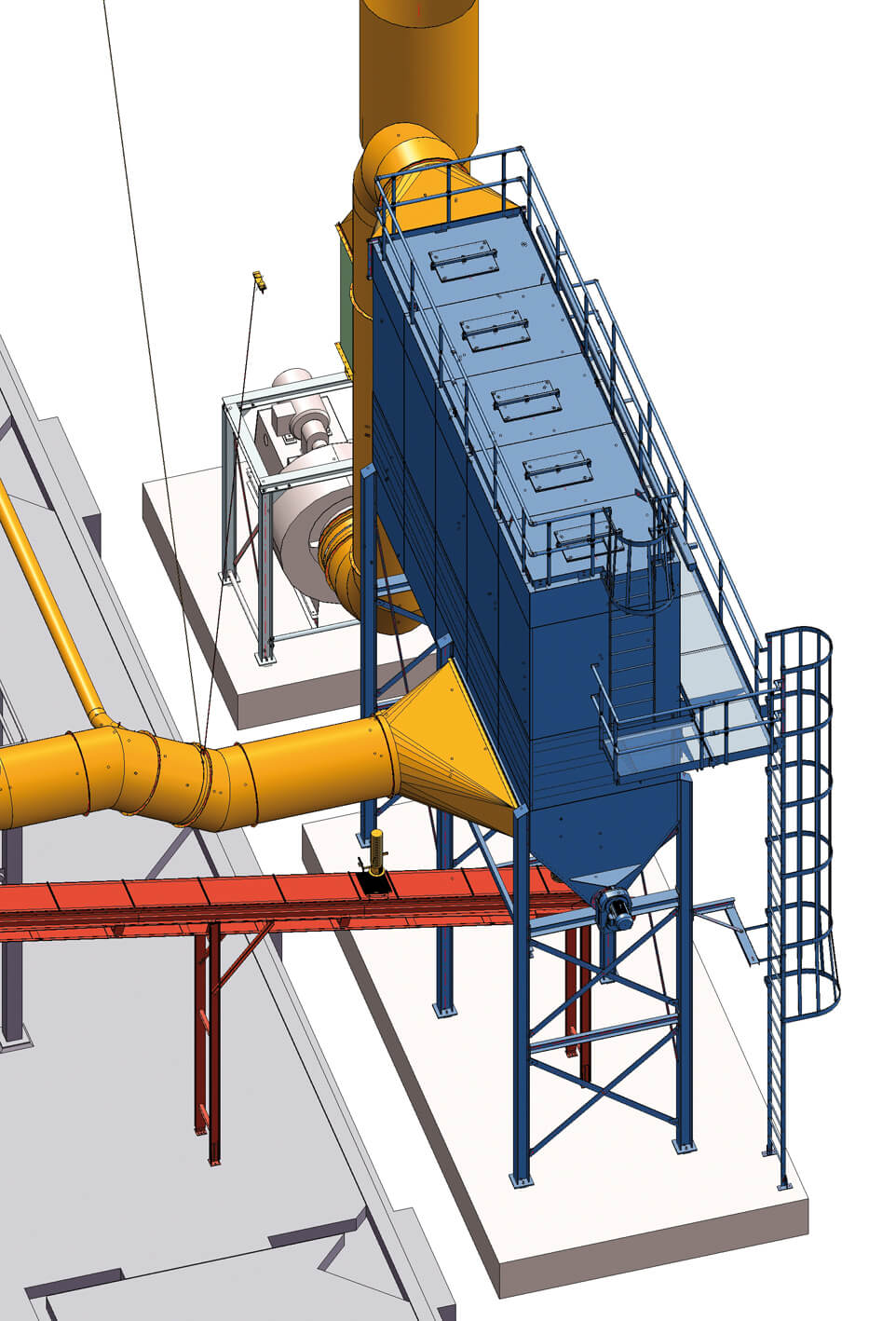

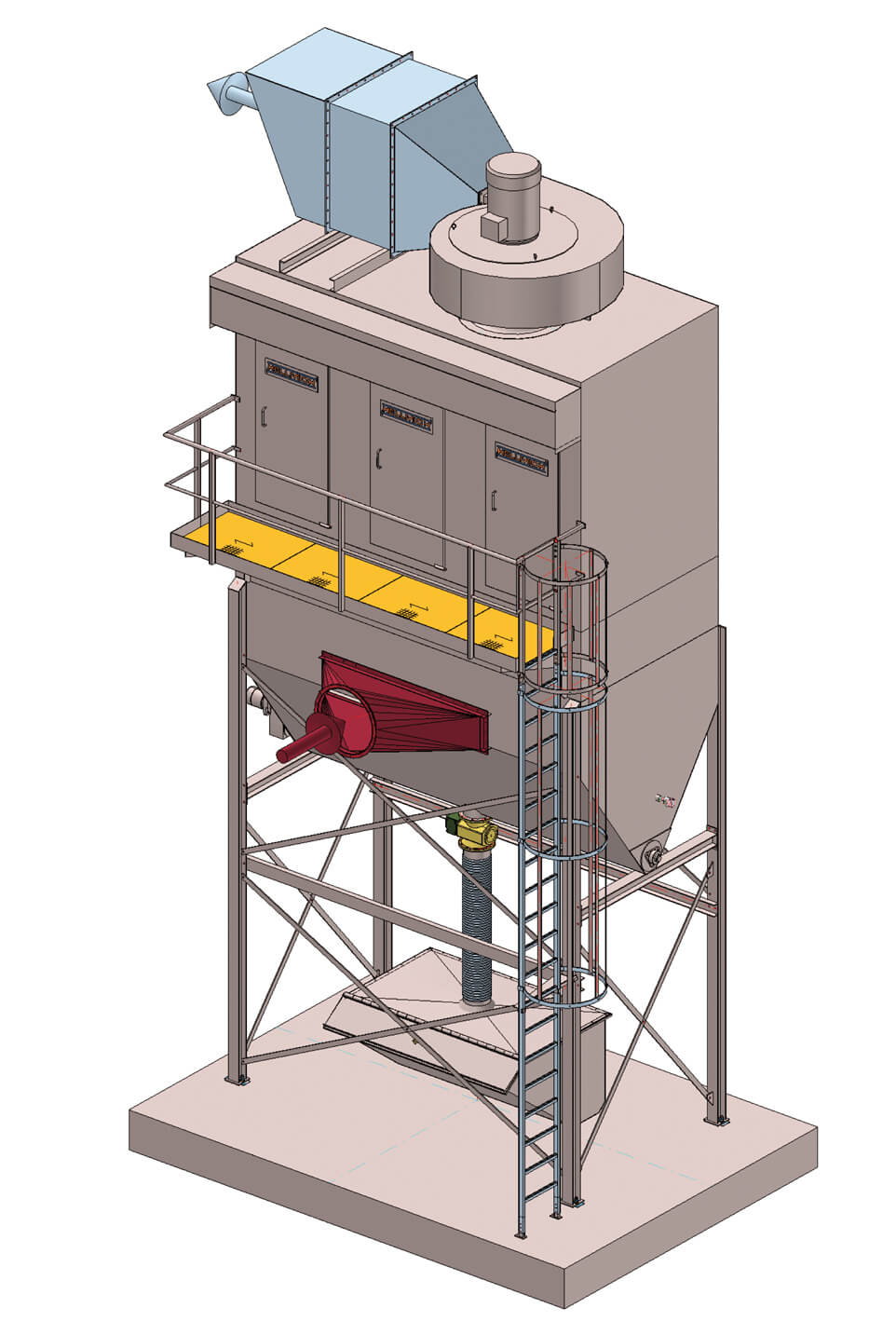

The HKD III inline filter plant is a fully automatic and continuously operating dedusting facility.

It can be used to simultaneous dedusting of several dust sources. The air quantities to be filtered range from 16,500 Bm3/h up to 120,000 Bm³/h.

Application area

Simultaneous dedusting of several dust sources.

The functional principle

The equipment is manufactured as a modular design. This means that several filter hoses are compiled into groups for each module. Cleaning off of the filter media takes place using a compressed air last via a solenoid valve. This form of cleaning off is extremely economic and energy-saving, since the blasts are only used when differential pressure measurement shows that they are required. Installation and removal of the filter hoses can take place without tools from an installation platform.

Equipment which is being operated in areas with frost risk is fitted with a valve heater and an additional protective cover for the solenoid valve. The pipeline routing required is designed individually. Hellmich only ever uses brand-name components for electronics or electronic components.

The filter hoses are made of various materials depending on the dust composition. The HKD III is used in the ceramics industry, limestone processing works, foundries, plastics processing and many other sectors.

Advantages

- Variable modular design

- Heavy-duty sheet steel construction

- Low energy consumption

- Made in Germany

The technology

The facility, which is made in a modular design, compiles several filter hoses into groups for each module. Cleaning off of the filter media takes place using a compressed air blast via a solenoid valve.