TOW - Automatic tunnel kiln car cleaning

TOW - Automatic tunnel kiln car cleaning

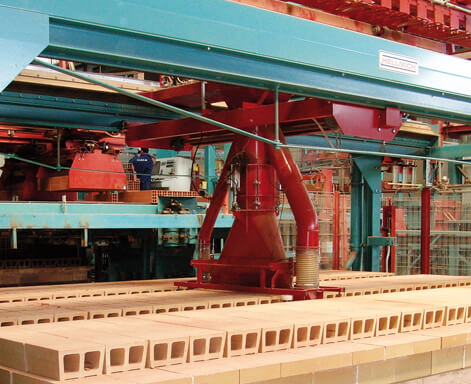

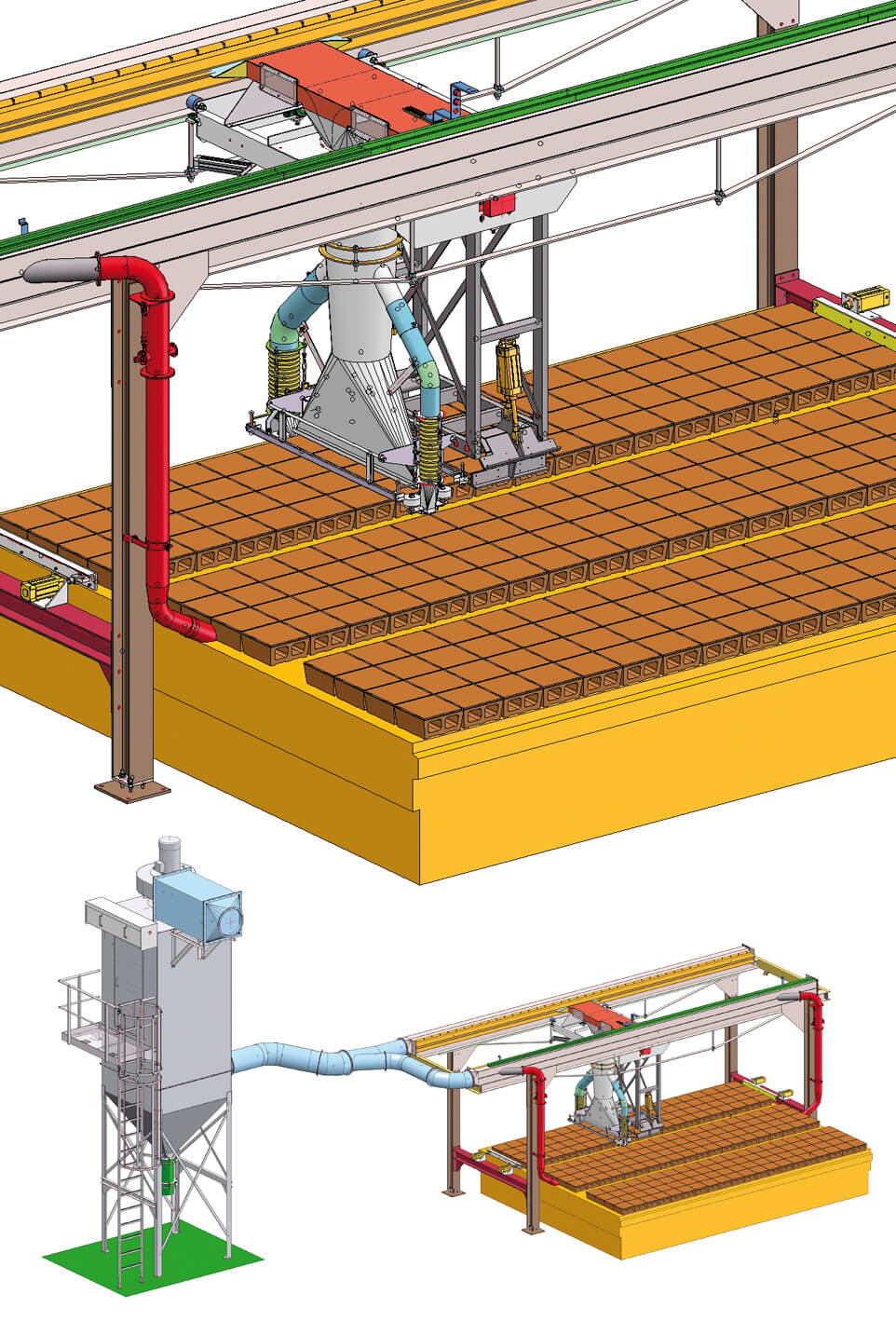

The dust extraction equipment allows the viaduct or hollow blocks and the tunnel kiln wagon plateau to be cleaned of dust and broken brick pieces.

We differentiate between cleaning using a fixed nozzle and cleaning using a movable nozzle.

The functional principle

The dust extraction equipment allows the viaduct or hollow blocks and the tunnel kiln wagon plateau to be cleaned of dust and broken brick pieces so that its service life is onsiderably increased, and so that product quality is raised.

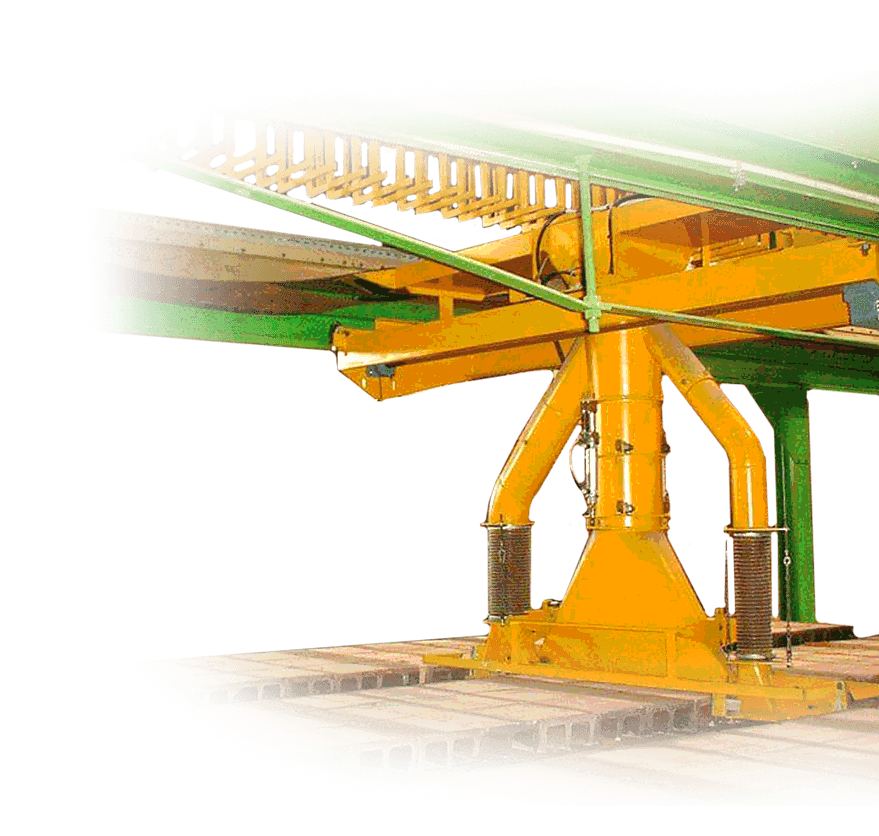

We differentiate between cleaning using a fixed nozzle and cleaning using a movable nozzle. In the case of car cleaning using a fixed nozzle, the tunnel kiln car runs through a frame from which the suction nozzle specially adapted to the setting plateau is suspended.

If cleaning is done using a movable nozzle, the airflow quantity required for cleaning is low enough to enable a smaller dedusting facility to be used. In this case, the nozzle runs across the individual rows and simultaneously cleans both the placing plateau and firing slits.

The nozzle runs into the park position after cleaning is complete. The car is then run to the next cleaning position and the suction procedure repeats until the entire wagon plateau is clean.

The hollow blocks can be raised with a lifting device for cleaning the car plateau. In doing so, the draught bricks are gripped with a gripper and then lifted with hoisting gear .After lifting, the lowered cleaning nozzle runs across the plateau and cleans it of small broken pieces and separating sand. The expansion joints are also cleaned out during plateau cleaning. The normal production routine is not disturbed in any way thanks to operation which is adapted to the unloading or setting machine.

Advantages

- Higher product quality

- Longer kiln car standing times

- Lower energy consumption

- More efficient cleaning

- Continuous automation and

production processe